Editor’s Note: This article is provided with permission by Matthew Forsyth. Matthew is a professional model builder and the owner of Forsyth Rail Services, specializing in O scale and Proto 48. Please visit his website at mattforsyth.com for more of his work and complete contact information.

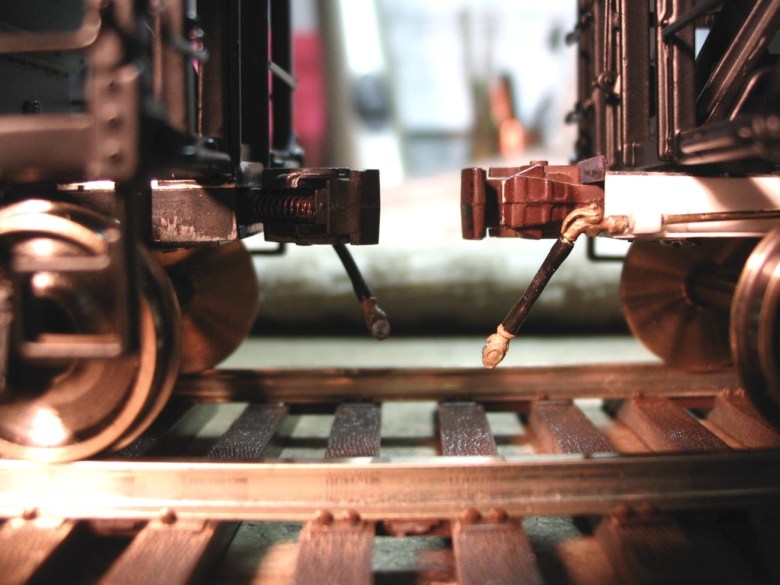

I had the great pleasure of spending an evening with the Maestro, Ben Brown, during the 2008 O Scale National, when it was held in Worcester, MA. Ben had been working on a system to prototypically replicate the brake hoses on “O” scale freight cars. And not just replicate them in appearance, but also in operation.

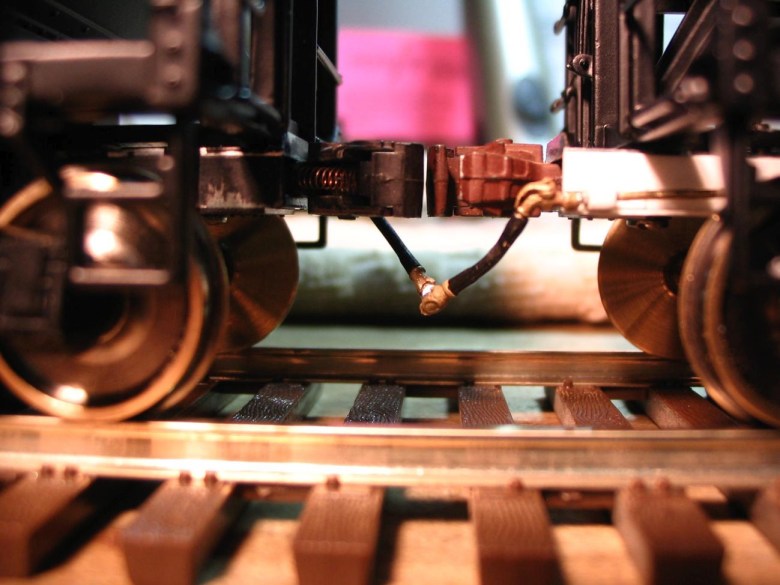

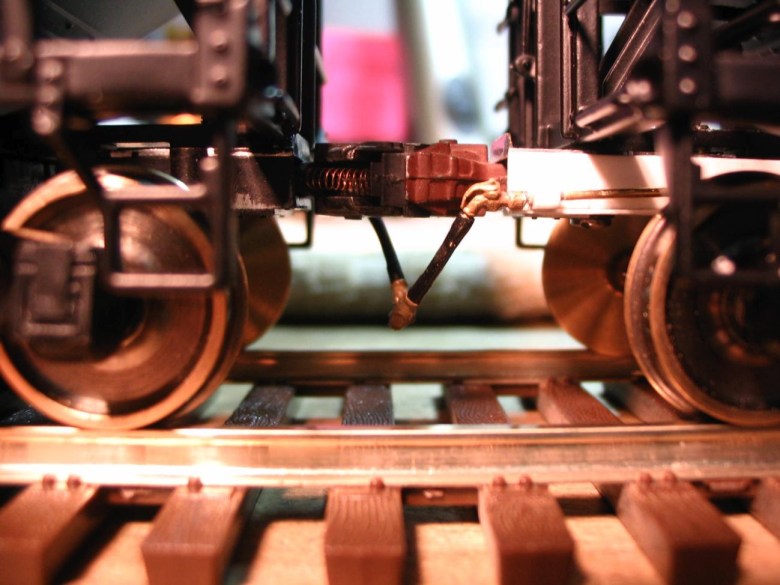

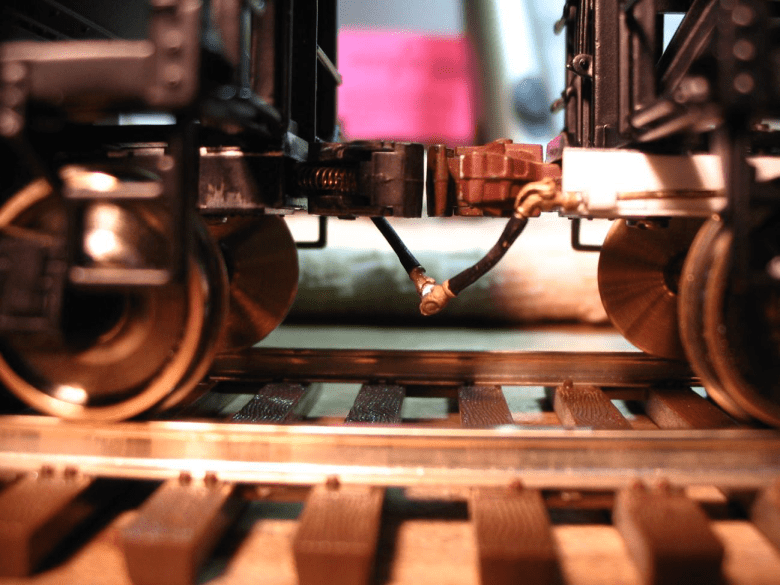

After much experimenting, he was able to find some high power neodymium magnets, that would allow the hose ends to automatically couple as the cars neared each other, and then stay coupled as the train operated.

The magnets are disc-shaped, 0.060 in diameter, and about 0.030 thick. They are so powerful, that a single magnet can hold a sheet of 8 ½ x 11 printer paper to the side of a refrigerator.

The second obstacle was finding a hose material that was flexible enough to be overcome by the magnetic forces and allow the gland hands to mate easily. He was successful there too.

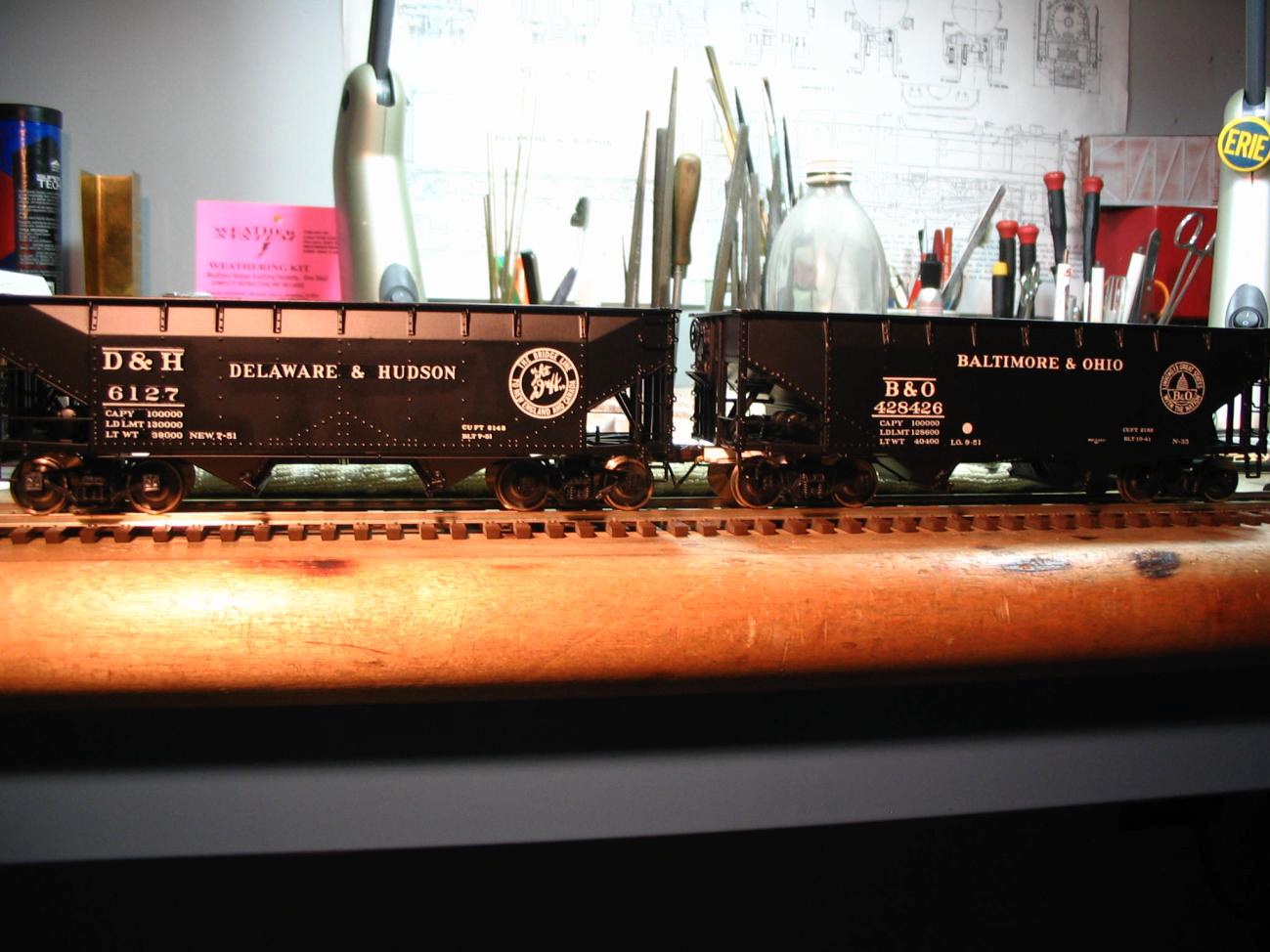

After seeing Ben’s cars operate, I was totally hooked and wanted to try out his new system. I have six cars equipped with this setup thus far and have no issues with them operationally. It’s such a pleasure to see each of the hose ends actually connected to one another as the train passes by.

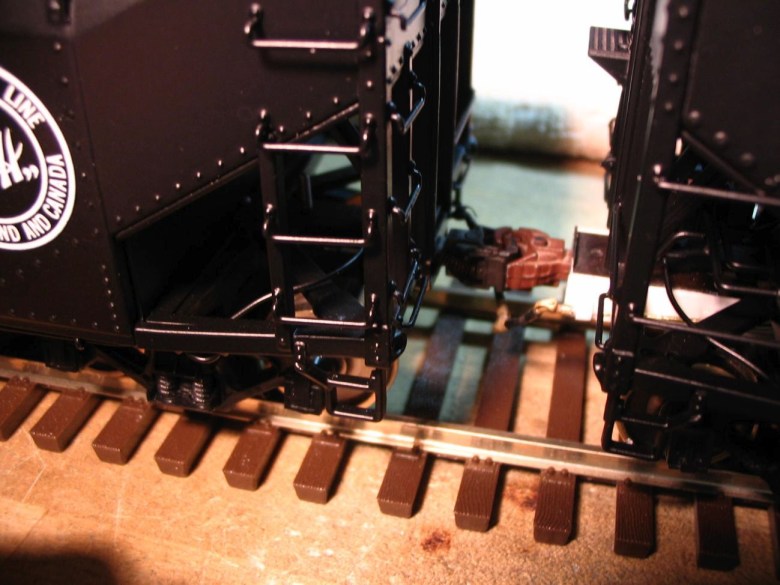

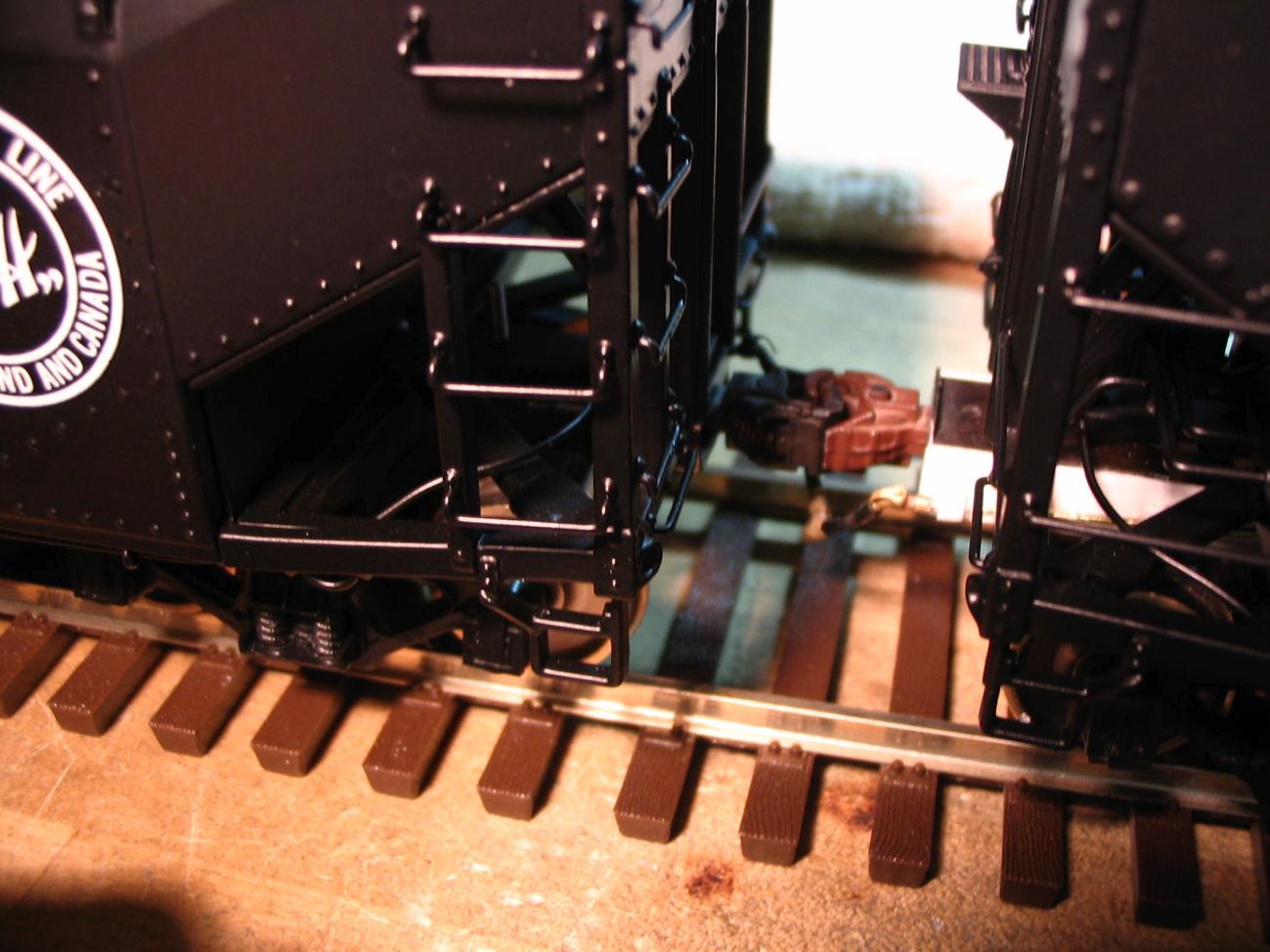

Here is a series of images that I took, showing the setup, as well as the actual coupling process.

My present plan is to equip every car and locomotive in my fleet with this ultra-realistic system.

On those rare occasions that the hoses do not mate automatically, it just gives the yard crew one more activity…making sure that all hoses are connected before performing a brake test, and getting the train underway.

Hi Shawn,

Do you have a source for the magnets and the hose used?

Cheers!

Brian Stokes

I know there was a discussion on the Proto48 group regarding this subject. I also did a search online and you can find a few suppliers like this one: https://www.ebay.com/i/111520961655?chn=ps&var=410518448188&norover=1&mkevt=1&mkrid=711-117182-37290-0&mkcid=2&itemid=410518448188_111520961655&targetid=934793861656&device=c&mktype=pla&googleloc=9029626&campaignid=10897343926&mkgroupid=106040611134&rlsatarget=pla-934793861656&abcId=9300403&merchantid=113682393&gclid=CjwKCAjww5r8BRB6EiwArcckCxf24r7UgHKg58gInpLVozdFz3tWPfAXFNxU1cBu-7khcUCDIB-OwRoCyYYQAvD_BwE

That is so cool! It will be a while before I get to building anything Proto:48, but I want to have this on my cars and engines when I do! What is the hose material that’s flexible enough and yet tough enough to make this work?