I am not a rivet counter, but I also appreciate the idea of finescale modeling. So, while I am not going to get bogged down in the specific history of certain passenger car side patterns and its proliferation across the country, I do want each of my models to be immediately recognizable as something that is highly plausible. Modeling mid twentieth century logging, through reading and research, allows for some pretty flexible creative license.

It is not a new idea that logging railroads, through ingenuity and necessity, built and utilized a wide variety of equipment. This ethos is something I’ve taken to heart and adapted to my modeling. My vision continues to morph and grow, making my freelanced On3 Pine Creek Lumber Company become so much bigger in my mind’s eye than it will ever realize itself in a layout. That I will most likely only ever have 12 feet of a shelf layout doesn’t need to be a limiting factor to what I build. Pieces of my roster can come and go, make appearances for photography or short run-by videos and then return to the display case.

This creative freedom frees me to build models of almost anything. If I can craft a feasible story of how a piece of rolling stock or locomotive ended up on my railroad, let it be built. Then as the story goes, through cunning and craft the top brass of Pine Creek Lumber Company (PCLC) amassed huge timber holdings in the Pacific Northwest. The lumber company weathered the depression and prospered through World War Two with an exploding regional population and government contracts in its pocket. While most other three-foot gauge operations folded, PCLC bought used equipment on the cheap and maintains an impressive roster of locomotives and rolling stock. If you think about it, all I am doing is emulating Rayioneer in its’ heyday.

This is how it has come to pass that I justify spending many, many hours of modeling time crafting ten cars of a unique passenger train. The Saturday Night Special on the PCLC brings family, gear, passengers, mail, a library, a hunting weekend, the executives and pay to the logging camps of its network. To keep its workers on the job and the money in its pocket, payroll is dispensed in camp using a payroll car. The loggers can continue out to town for the dance in a coach or combine on the train, but the PCLC hopes most of its workers and the cash they hold stays in the woods.

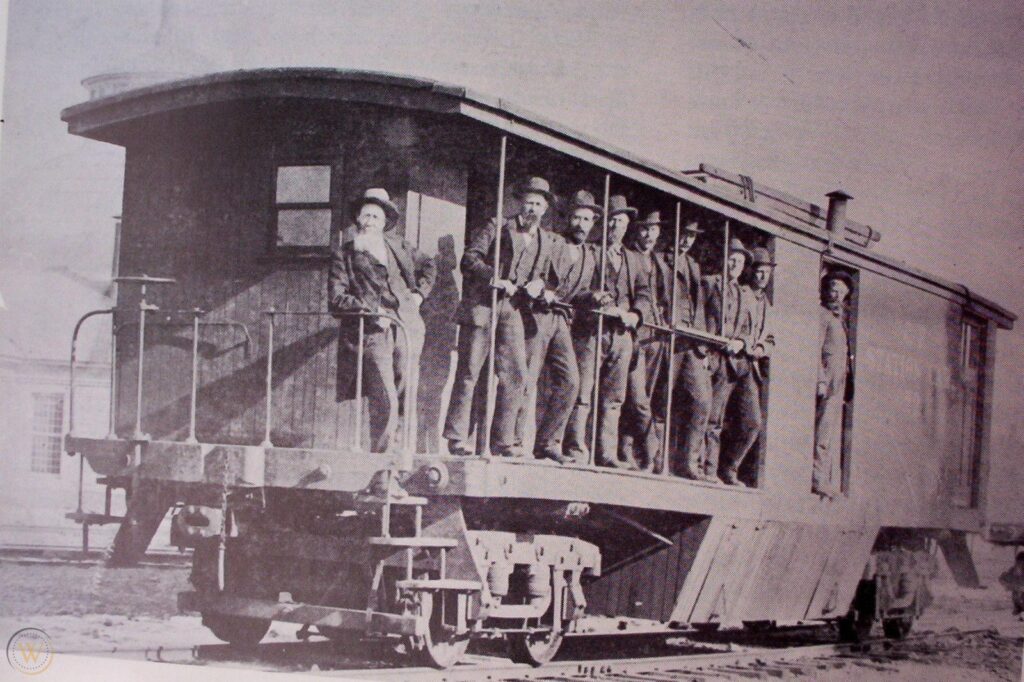

All it can take is the label on a box to get the ball rolling, and this time it was on an old Ambroid HO kit for a standard gauge payroll car. Beyond the image included in the instructions for the kit, there was very little prototype information to go off. This ambiguity really allowed me to flex my creative muscle and the years between getting the idea and starting the build offered plenty of opportunity to generate a list of potential details to include.

The payroll car ended up being the 8th car I started in a ten-car set and that helped me have a lot of the typical designs and build methods at the ready. How to finish a car ends and detail the underbody already in my pocket, I could focus on a few of the more unique aspects of this car. The offset wall and exterior walkway being the biggest challenges to overcome. Having just completed a couple of Labelle and Wiseman Model Services kits also provided the understanding of how these models are built and masters made. Fortunately, for modeling always seems to be a series of lucky breaks, Wiseman’s D&RGW Parlor car kit was the appropriate length and window arrangement to act as the base model to cut up and modify.

Every build I start follows a pattern. First frame, then body, set the truck bolsters for coupler height, complete the under-car details, followed by car ends and finally the roof before installing couplers and air hoses. Each of these stages usually requires specific detailing and multiple stages of paint. And if I think of each of these larger assemblies as a single component with a list of tasks to be completed before moving forward, it breaks a complicated model into manageable pieces. Treating the build process as a set of assemblies helps me remember all the details I’ve thought of during the model’s long gestation period.

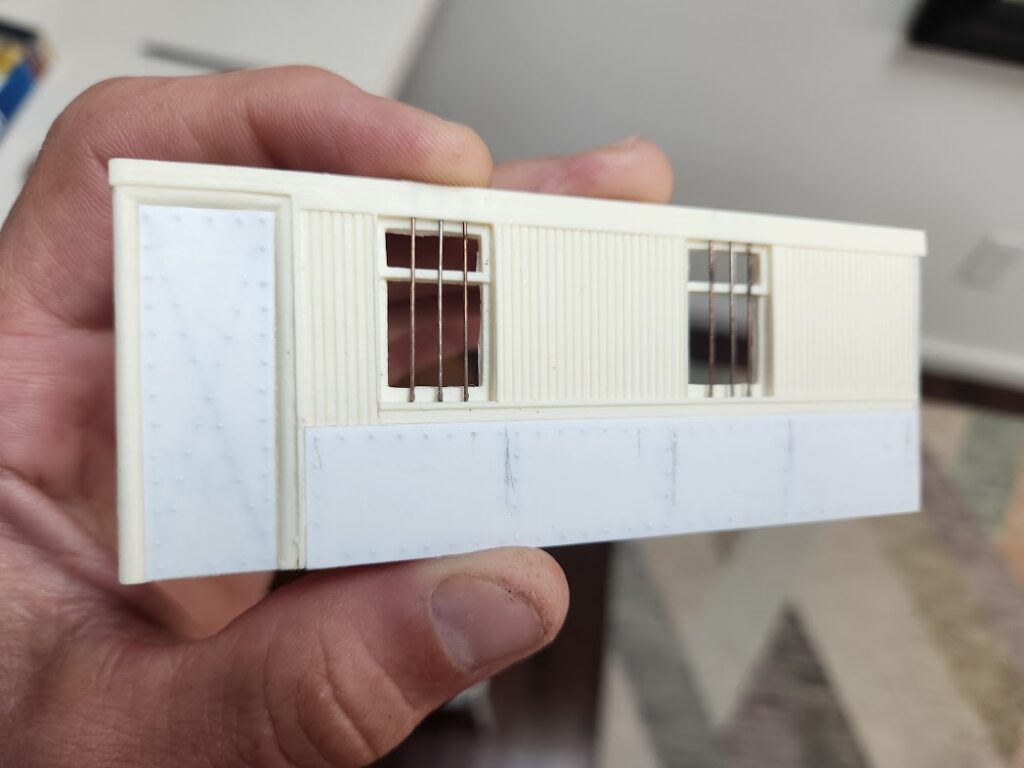

For instance, this process gives me time to think of how to drill out the resin car sides for the window bars and create patterns for the armored sides. It provides prospective and motivation for tedious tasks like hand cutting and framing all the interior windows. And while working on the early stages, if I look forward to the later assemblies, there is time to shop, order and wait for all the interior details to arrive. It keeps everything on track, moving forward and avoids the dreaded pause. The momentum killer which often leads to a projects shelved status, never to be completed. Meanwhile I am forever fiddling with and dry fitting together all the pieces to make sure when I make the major cuts to the walls and glue parts together, everything is going to line up and fit.

And then surprisingly, there is this magical moment at the bench where I look down, drop on the roof and see it. The physical realization of this creative idea. Suddenly I am holding in my hands a near match of some picture I had drawn in my head and it is what brings me back to the bench time and time again, working out some way to build all these pieces that I imagine my railroad could own.

This fictional growth is a cool piece of the modeling puzzle to me as well. I started building these ten cars in December of 2024. Here it is nine months later, and the Pine Creek Lumber Companies story is still developing. I’ve built a train long enough that I can’t actually run it all together at once like I imagine. Yet it doesn’t matter, because in the same mind’s eye that imagines each individual car, I can see the whole train lumbering through the woods on Saturday night, headed to pay the fellers and donkey punchers.