This past spring Jeff Johnson let it be known that 2025 would likely be the last year the Pacific Model Loggers Congress would be held at the Camp 18 Logging Museum and Restaurant in Elsie, Oregon. For the last few years, I’ve added the date to my calendar and neglected to attend. With the 20th edition possibly being its last, the date was written in red ink. As the weekend approached, I readied a few contest models and left the house pre-dawn for the trek to the foothills of the Tillamook range.

The event itself was fantastic. I chastise myself for not making it years prior and am disappointed it probably won’t be happening again. The modeling contest was great, taking home a pair of awards was better. The presentations were awesome and spending a day talking about modeling was refreshing. The unexpected highlight of the day was taking in the museum at Camp 18.

Inside the building, there is an extensive library, great examples of modeling with logging artifacts and memorabilia covering almost every surface. Outside, underneath years of accumulating rust, the collection really shines. The property boasts more antique logging equipment than a chainsaw has teeth. From standard gauge railroad equipment to a working blacksmith shop to a dog house saved from a logging camp. I walked the property during the lunch break and photographed nearly everything. But there was one piece that really grabbed my attention.

I later would learn it is called a self loading log truck. And while there isn’t a ton of evidence of them online, when the question is posed to the right families with a history in logging, they often had one in the back lot or knew of one amongst friends. The truck at Camp 18 was most likely a GMC CCKW 2½-ton 6×6 truck. One of approximately 550,000 trucks built for the war effort between 1941 and 1945. When I started researching building a model of one it seemed like fate that there is a very inexpensive, but high quality model of them being made in the Denver Military US Army CCKW-353 Cargo Transport Truck. So inexpensive that I bought a lot of four of them with the intention to batch build a small fleet.

With the winch built into the model already, the loader assembly would be fairly simple to fabricate, the most tricky area being atop the boom tower. Building four at once really paid off here, measuring twice and cutting four times. The mini assemblies built into a significant amount of modeling quickly. With a box full of styrene waiting to be cut, and a pile of brass log bunk castings already in the part drawer, I felt like the models were practically in the bag.

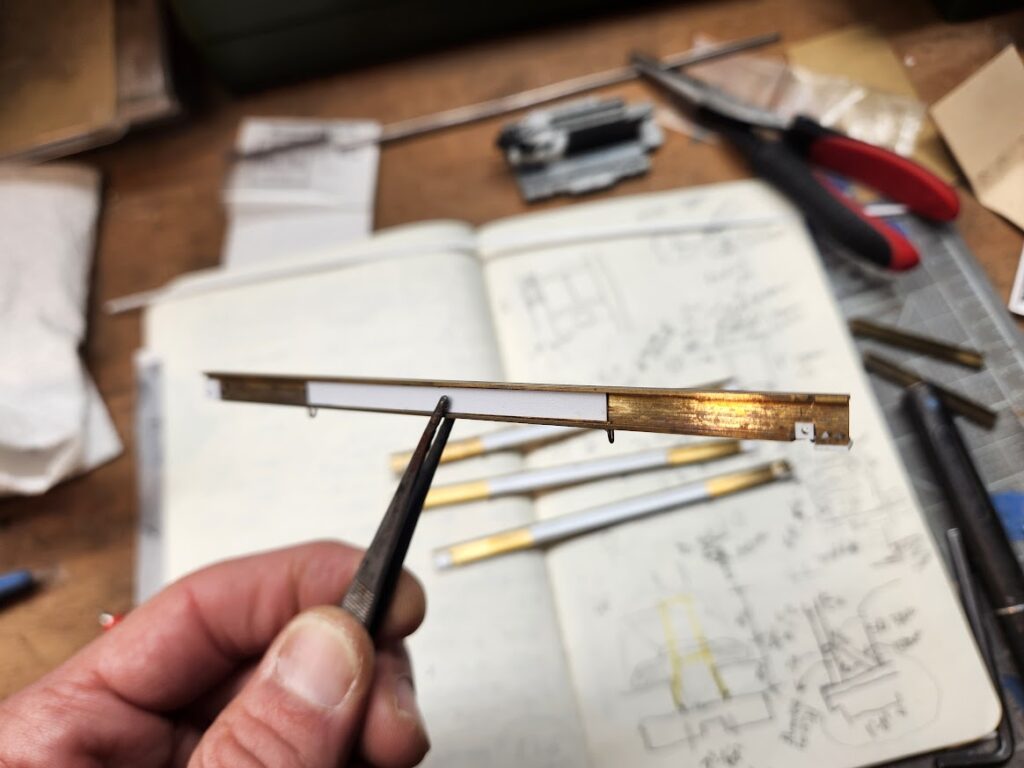

The boom arm from front to rear measured out to be about twenty scale feet long. After cutting some styrene to length and testing it over my finger, it was obvious that while not extreme, with any sort of tension from the rigging line, the boom arm was going to twist and bend. This wasn’t ideal so I hunted up some brass I-Beam pieces on the internet and patiently waited for my mail carrier.

It wasn’t so much of a delay because there was plenty of modification and prep to do to the truck bodies, frames, wheels and interior pieces. All times four. Most of this work would come in the initial painting and weathering. I like the look of the deep orange in vintage logging equipment, so that is the direction I went with a can of Tamiya spray paint. With the trucks torn down to their shells and all the pieces separated, everything went out to the alley on a dry, sunny day to be transformed from army green to forest logger.

The finish was terrible. So bad that I almost popped open the adjacent trash can and pitched it all. I hesitated on trashing it, but once it was all dry, I found the box the trucks were shipped to me in, dumped all the pieces in and shelved the entire project. There isn’t photographic proof of my disappointment.

And then the mail carrier left the brass I-Beam in the mailbox and saved the project. It forced me to get the box out again and re-think my mistakes. To keep these trucks even imaginatively close to my modeling time frame, they’d have to be in relatively good shape. Yet, I was going to need to hit the paint pretty hard to hide how bad it looked. But with some creative fading and dirty washes, being careful to not rust them out too badly, I was able to transition my crappy paint job to a believable patina.

With that challenge overcome, a serious session of re-assembly was needed before finishing the loading boom assemblies for the four models. Each model has 11 rubber tires that needed to be stretched back onto their rims. This was made significantly easier by soaking them in hot water first. The interiors and window glazing essentially snapped back in and the trucks were almost ready to roll once again.

Each little assembly was painted and weathered before being fixed to the model. So by the time each of the four were being rigged with cable, blocks and log tongs, the models themselves were finished. Finished except for rigging the bunks with chain which proved to be the most delicate and finicky part of the whole project. One model was completed without a load so that I can ultimately model a couple different scenarios. I have a picture of a wood cutters cabin in one of the Saginaw Timber logging camps that could feature any of these trucks perfectly.