Before I started focusing on On3 finescale modeling with my freelanced Pine Creek Lumber Company, my modeling was being done to showcase on a local On30 modular layout. I really enjoy modifying Bachmann’s On30 two truck shay locomotives into unique pieces that fit my whimsy. And because logging railroads seemed too often do the same with the locomotives they’d buy new from Lima or second hand from a competitor’s operation, my creative choices (within reason) could be dropped in the woods almost anywhere.

I slowly waded into the waters of stock locomotive modification by adding my own cast details and then replacing the stock cab with a laser cut kit. The first Wiseman Model Services conversion kit I built was eye opening, like when you finally get to belly button depth in cold water. It’s a little scary, but once you have a unique finished model, it is exciting. Seeing the model stripped down offers a new perspective. If you remove the entire superstructure, you realize almost any two-truck shay is possible.

When my modular railroad club, the Moose Creek Logging Company, built a set of new mining modules I started to envision an open cab shay to run on it. My enthusiasm initially for spending the time building an open cab shay wasn’t very high but when I researched how I could eventually build one, I kept coming back to Jim Oliver’s Echo Mountain 13 ton shay. It was exactly what I wanted to emulate if the time ever came. I knew this would require going up to my neck in some pretty chilly water. As it often goes though, a model is just meant to be built, even if it is one you might not have had any interest in building a few months ago.

For those who are not familiar, the Echo Mountain open cab shay is a pretty unique On3 brass locomotive. They come up for sale from time to time but are expensive, not to mention gauged 1/16″ too wide for our club’s On30 layout. The model has a very short water tender on the rear, a very sparsely adorned t-boiler and really interesting both narrow and wide stack. To successfully build an On30 version, I would have to modify everything on the stock Bachmann model above and some below the frame.

An innocuous conversation with vendor Heather Clark at a local train show suddenly dropped all the pieces into play. She mentioned that years ago she had bought a large portion of the late Jim Oliver’s estate and all she had left of his ¼” scale stuff was “a box of random 13t shay pieces”. With the deal struck and the parts in hand, I suddenly had the two pieces that were going to be the most difficult to scratch build. Brass extras of the tender and cab as well as the unique stack.

And this is the second most exciting part of any build for me. There is a lot of time spent at the front end where I look through tons of pictures and start trying to source all the parts needed to create the vision I have in my mind. There are always one or two pieces that are the crux of this collecting process and until those are found I don’t begin any other part of the project. With the tender and stack in hand I had the green light for gathering a suitable locomotive, details from various vendors and the DCC electrical components.

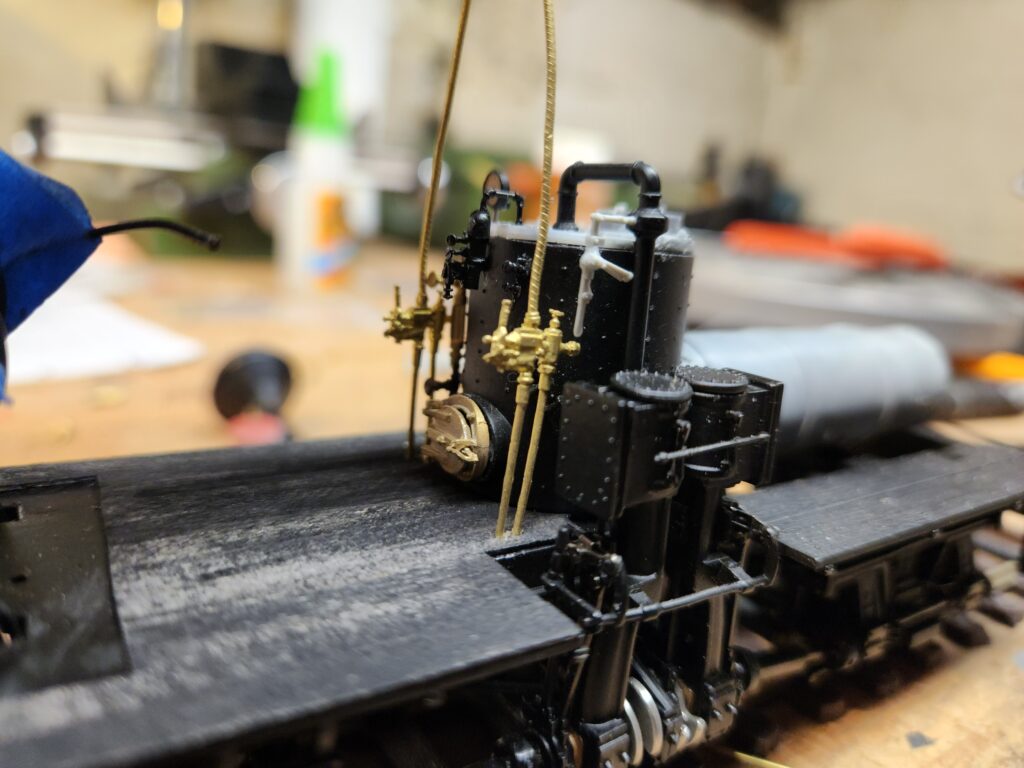

Having the tender and cab prefabricated my focus in building the model would be on the boiler and backhead. The boiler on the Bachmann model was close, but the cast-on sand dome was a far cry from the simple, bucket looking dome on the Echo Mountain Model. This small detail was pretty crutial for the overall look. After test fitting some pieces of a Precision Scale kit I have, I decided to use the vertical section of the Bachmann boiler to house the motor and to provide rivet detail the PSC part didn’t have. And then, I’d use Precision Scale parts for the horizontal boiler, vertical boiler top and smoke box door.

PSC offers the boiler in two pieces of molded plastic or for about 50% the cost a single cast brass piece. In retrospect, buying the brass piece would have been much simpler. After gluing the two halves together I needed to fill and sand the joint over multiple layers to get the piece to look smooth and appear to be one piece. But this was necessary since the boiler would only have the sand dome and stack atop it, leaving a lot of real estate for scrutiny. Nothing could ruin this model like a long, unrealistic seam atop the boiler.

I built the sand dome from scratch using brass tube, a strip of card stock and the trimmed cap of an extra fat Sharpie marker. After some filling compound and much sanding this piece became a pretty good facsimile to the Echo Mountain part. I turned the small dome topper using my drill press and a needle file. The handles are left over wire from the resistors I used in the DCC LED installation. The sand dome and boiler modification is subtle but makes the model’s appearance significantly different from the original Bachmann model.

Scratch building the sand dome was also an example of something I need to remind myself over and over. When I am trying to build something, it doesn’t matter what it looks like unpainted. If the shape is correct and everything is sanded smooth, no one will know it isn’t a perfect fancy brass part. The dome looked very rudimentary at first, but was perfect with a coat of black paint.

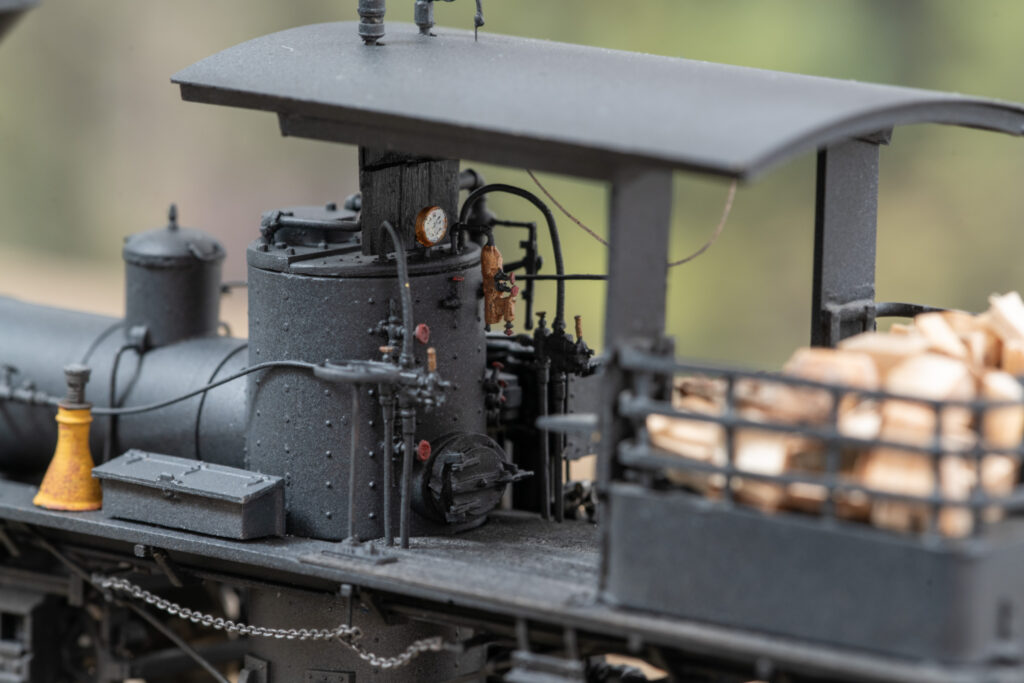

With the superstructure sorted, I spent a significant amount of time planning and placing the backhead details and piping the injectors, pop valve and whistle. All these details came from Kieth Wiseman, PSC, off the Bachmann model, or were scratch built. The reverse lever was a fun detail to build and add onto the engineer’s side. It is a function of the real locomotive that I needed to study to learn how it would have looked and operated in real life. With everything being so open and exposed it all needs to be realistic, and I did my best to build it as such.

Another fun detail of this model is the manual brake wheel and chain on the fireman’s side. I removed the steam pump from the Bachmann model, rerouted the bottom side piping and attached the chains to the factory brake rigging. For all these details I was repeating the design of the Echo Mountain model as best as I could. The Lee Town brass headlight casting that I found for a dollar at my local hobby shop is the one significant alteration to the look of the Echo Mountain model which was a box style headlight. I felt this was a way to subtly make it my own.

Adding electronics is always one of my least favorite activities. A necessary step though, I stuffed a Soundtraxx TSU-1100 Steam2 decoder and a 28mm round speaker into the tender and hid the current keeper inside the front section of the boiler. The PSC boiler front is hollow, unlike the Bachmann boiler and was a lucky break allowing it to fit. A slightly depleted pile of fresh cut wood rests atop the tender.

I feel like the wood pile is often overlooked and using real wood is head and shoulders better than a plastic casting. I’ve had a journey to my current method, where the first pieces I cut were almost as laborious as splitting real pine. Now, I am using a powered mini chop saw to cut the pieces to length. And then I put a strip of double-sided duct tape onto a scrap 1×4” piece of lumber. Each “round” is stuck down, and I use a metal box cutter and claw hammer to “chop” out wood pieces. The double-sided tape keeps everything from spilling all over and allows each round to be cut eight or ten times without needing to be reset or put on end again. In just 10 minutes I can have enough wood for multiple piles.

By realizing this model and creating what I feel is a pretty faithful tribute to the Echo Mountain shay, I think I am ready to take the plunge and go in over my head. It is time to strip one of the Bachmann models down, cut the frame to lengthen it and build a 20-22 ton shay in On30 like Precision Scale used to build in brass. To build a model that looks familiar yet is absolutely unique.